Nos compétences

Prototypage

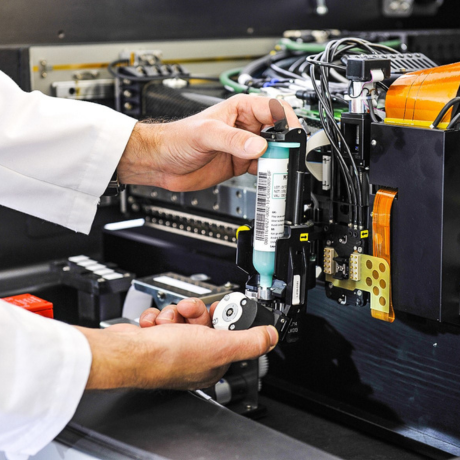

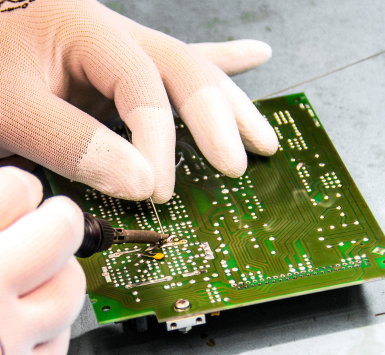

Vous êtes à la recherche d’une équipe de production fiable et expérimentée pour la réalisation de vos prototypes ? Ne cherchez plus ! Nous avons les compétences nécessaires pour répondre à vos besoins et optimiser votre processus de fabrication. Grâce à notre machine jet print de pointe, nous pouvons déposer la crème à braser avec une précision extrême et sans l’utilisation d’écrans de sérigraphie coûteux. Vous bénéficierez ainsi d’un service efficace, rapide et économique pour vos projets. Faites confiance à notre expertise pour mener à bien votre projet de bout en bout.

Industrialisation

Fort de ses presque 30 années d’expérience, Becker Electronique vous apporte ses compétences et son expertise quand à l’industrialisation en petite et moyenne série de vos cartes électroniques.

Notre responsable méthode s’occupe de définir les différents processus, réalise les gammes d’assemblage, les outillages, selon les dossiers et recommandations de nos clients.

Achat et approvisionnement

Le service achat de Becker Electronique s’occupe de l’approvisionnement des composants électroniques en s’assurant de respecter la qualité, les délais demandés, tout en optimisant le prix.

Grâce à ses antennes aux USA, en Allemagne et à Taiwan, nous pouvons accéder aux stocks dans le monde entier sans être impacté par la répartition des composants dans les différentes zones économiques.

Une fois la matière approvisionnée, notre équipe logistique s’occupera de stocker les composants dans des conditions optimales. Les composants sensibles seront placés dans des armoires à environnement contrôlé (température et hydrométrie) selon le JEDEC J-STD-033C

Nous sommes également habituer à travailler avec tout ou partie de la matière, fournie par nos clients.

Production

L’atelier de production de Becker Electronique est conçu pour être réactif et adaptable afin de s’adapter au mieux aux différentes demandes et spécifications techniques de nos clients.

Il est composé de :

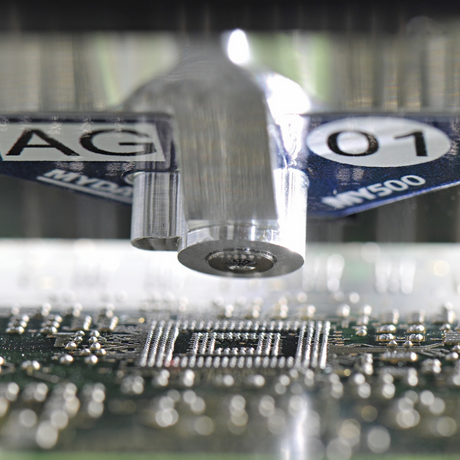

2 lignes d’assemblages de composants CMS pouvant poser tout types de composants (BGA, …) et de toutes tailles (01-005, …)

– Machine de dépose de crème à braser

– Machines de dépose de composants CMS (20 000 pts/h) équipée d’un vérificateur électrique

– Four à refusion 8 zones

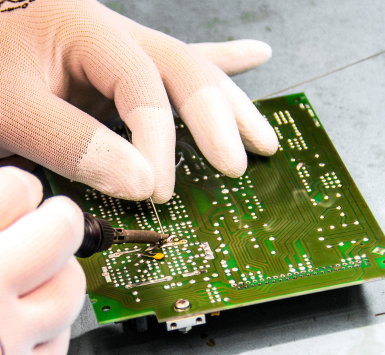

Ilôts d’assemblage traditionnel

– postes aménagés selon normes ESD

– dispositifs de soudures à vagues: SnPb & Rohs

Afin d’apporter le meilleur service à ses clients, Becker Electronique investit de façon continue dans ses moyens de production. Cela passe par l’amélioration du parc machine et par la formation continue de notre équipe, afin d’aider nos collaborateurs à monter en compétence.

Test et contrôle qualité

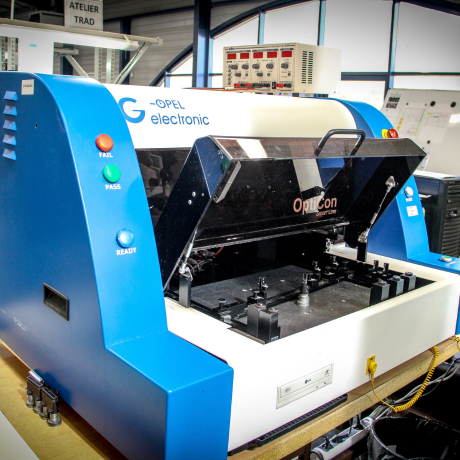

Durant le processus de fabrication, toutes les cartes électroniques sont soumissent premièrement à un contrôle visuel réalisé par nos opérateurs, et également par une machine de contrôle optique, pour tout les composants montés en surfaces.

En fin de processus, les cartes sont vérifiés par un technicien qualité, certifié IPC-A-610 Classe 3.

En fonction des exigences de nos clients, les cartes ou systèmes (une fois les cartes intégrées) sont soumis à un test fonctionnel et/ou à un banc de test.

Intégration et câblages

Afin de servir au mieux nos clients, nous nous occupons d’intégrer les cartes électroniques que nous assemblons dans différents types de systèmes:

– boitiers mécaniques ou polymères

– armoires électriques

Nous nous occupons également de câbler les différentes cartes entre elles, de les relier au disjoncteurs, afin de livrer à notre client un produit semi-fini, voir fini.

Cette étape d’intégration dans nos locaux, nous permet de réaliser les différents tests fonctionnels exigés par le client permettant ainsi livrer un produit fonctionnel.

Services connexes

Afin de répondre au mieux aux besoins de nos nos clients, nous effectuons également:

La tropicalisation de cartes électroniques, ce qui permet de les protéger d’un environnement agressifs (atmosphère marin, humidité, poussière, …).

Service Après Vente et la maintenance de système: nous disposons d’une machine permettant les opérations de réparation des cartes électroniques, et ce pour n’importe quel type de composants (BGA, VPGA, …)

Etuvages

Lavage des cartes par processus aqueux

Processus de déverminage (accélération du vieillissement des cartes).

Programmation de CIT